Investing in a new era of engineering productivity

By Brent Bradbury, VP Software, Stoke

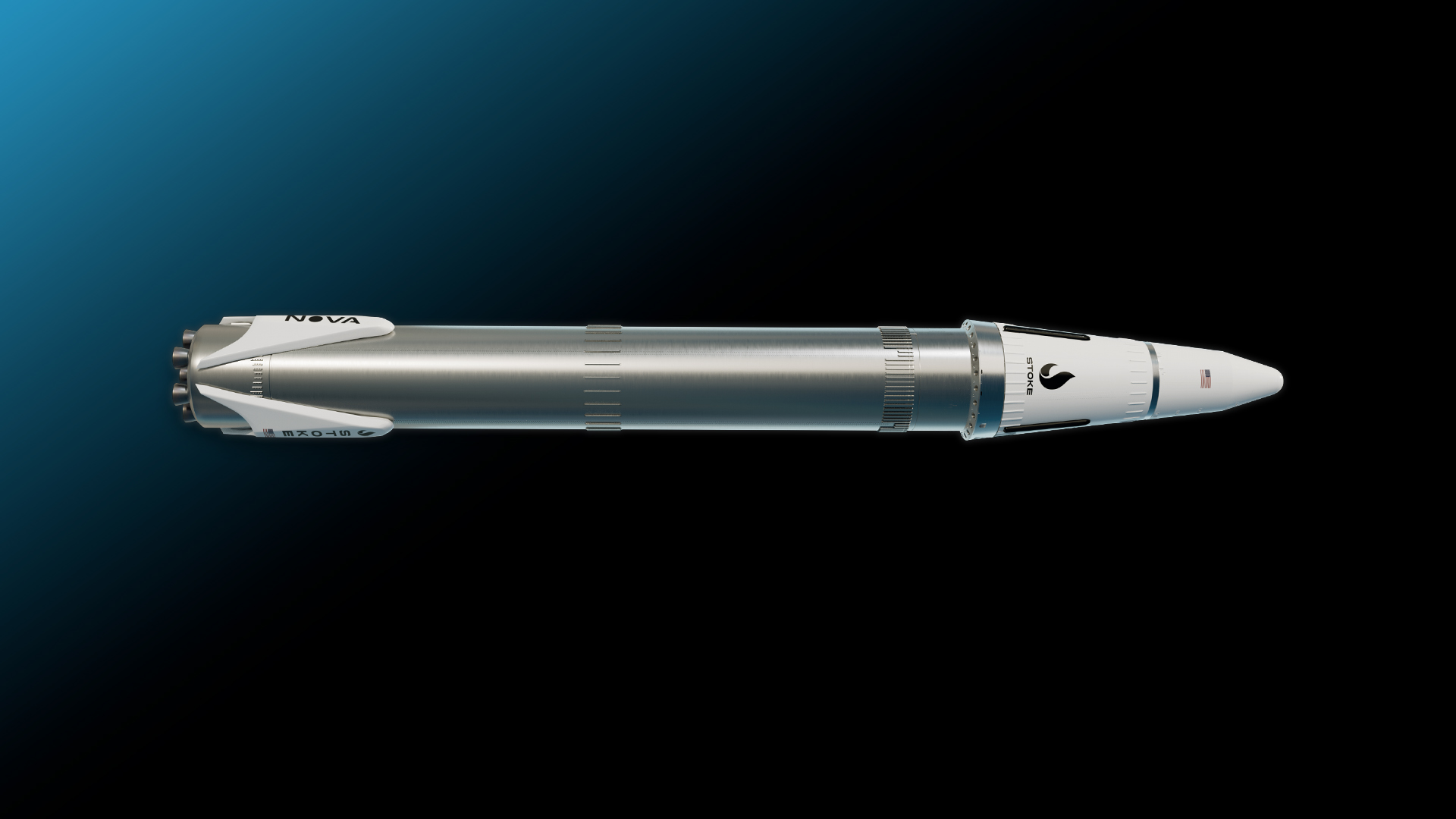

Stoke Space’s $260 million investment is about more than just reusable rockets: it is an investment in a new era of engineering productivity. Developing groundbreaking hardware isn’t just about innovative designs: truly executing means building fast, iterating quickly, and maintaining robust traceability, all while tracking literal nuts and bolts.

In 2025 we’re thrilled to be significantly expanding the Fusion by Stoke Space team, so that we can continue to drive lessons learned into the product from the hundreds of high-cadence team members that we support each day.

The essence of speed

Since 2021, we’ve been reimagining traditional engineering processes from the ground up, and capturing these lessons as design principles within the Fusion by Stoke Space software ecosystem. Here are the rules we follow:

1. Unify Process Ownership with Software Configuration: Traditional software often silos configuration control within IT teams or external vendors, delaying adjustments. We flip this model. By empowering process owners—those closest to the work—to configure the software directly, hardware companies ensure tools evolve naturally alongside goals.

2. Ensure Always-On Traceability: Traceability simply won’t happen if it incurs a cost of time, confusion, or distraction for users. It must emerge real-time as users engage with tools that facilitate their day-to-day jobs. We have been meticulous in capturing and surfacing every change, so that teams always have access to accurate, up-to-date information. This continuous traceability allows a quick look back into the past to identify issues, verify compliance, and understand the complete history of any piece of hardware.

3. Allow Continuous Release Processes: Continuous design and release processes allow teams to move forward incrementally, even when designs aren’t fully defined. High cadence teams keep the shop running: design work elsewhere on a complex assembly need not block progress making its piece parts. Software tooling must enable this, not prevent it.

4. Visualize Work to Enable Self-Organization: Dependencies and work items are important to visualize, but not always to enforce. Manufacturing processes are complex, and many software tools make the mistake of trying to represent and constrain every possible path. The opposite is more efficient and more pragmatic: when teams can organize the work around goals and filter out the noise, they can make informed tactical choices for what to focus on and immediately start executing.

Lifting all boats

While Fusion was born from Stoke Space’s mission to revolutionize space exploration, its benefits extend across hardware-driven industries. We are thrilled to be leading the way – to and from space, and to a faster, better future for all who build.